Hi Friends!!!

This blog is very useful for the correct installation of a centrifugal pump. I am not sure if the same is applicable for all types of pump , however This is applicable for all types of centrifugal pump.

Today i am going to write on the basic accessories required for the smooth functioning of the pumpset.

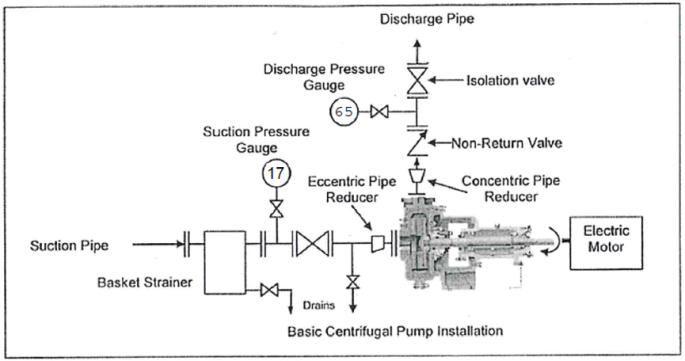

The image shown is the simple Layout of the Installation of Horizontal Centrifugal Pump.

Below are the important parameters and their short description. These parameters play a very important role in characteristics of centrifugal pump.

A) Suction and Discharge Pipe : The liquid is transferred by the pump from one location to another through a pipe. The pipe which is connected to the suction flange of the pump is called Suction Pipe , whereas the pipe which is connected to the discharge flange is called Discharge Pipe.

B) Eccentric Pipe Reducer : For smooth functioning of the pump , the pump should get adequate water and should not attract air , for this reason the suction pipe is always larger as compared to the pump suction flange.Also many times if there are multiple pumps connected via a head then suction pipe is much larger than the suction flange. For this reason a reducer is required.

Why reducer should be Eccentric only? As of now just consider it as a thumb rule , i will take this topic in detail in another blog post.

C) Concentric Pipe Reducer : Just as the suction pipe has to be bigger , the discharge pipe can also be bigger at times. It is not compulsory for the discharge pipe to be of higher size as compared to discharge flange however it cannot be undersize otherwise it can lead to frictional losses causing Head to increase. The suction and discharge pipe size needs to be given by Pump manufacturer.There are many reasons why a discharge pipe can be larger than discharge flange eg : it is connected to some other source in line etc. Hence to match the piping a dicharge pipe reducer is used.

Again the same question …. Why should it be concentric?? As of now just consider it as a thumb rule , i will take this topic in detail in another blog post.

JUST REMEMBER IN SUCTION SIDE , REDUCER SHOULD BE ECCENTRIC WHILE IN DISCHARGE THE REDUCER SHOULD BE CONCENTRIC.

D)Valves : 1 No Isolation Valve in Suction Side and 2 Nos Valves ( 1 Isolation/Throttling Valve and 1 Non Return Valve) in Discharge Side.

Isolation Valves : Generally for Isolation and Throttling a valve is installed in discharge side.

Incase of any maintaince of the pump is required then the valve is fully closed so that the discharge pipe is isolated from the pump.

Also generally pressure is controlled in discharge with the help of this valve hence instead of Isolation Valve a Throttling valve should be used.

Isolation Valve is also used in Suction side. It is for the same purpose ie Isolating suction pipe from Pump during Pump maintaince.

Non Return Valve (NRV) : This is mainly used inorder to avoid the backflow of water when the pump stops. Backflow of water cause reverse rotation of pump which is very harmful for the health of the pump.

An NRV is always installed first after which Isolations/Throttling Valve is installed.

Types of Valves :

a) Isolation Valve : Gate Valve , Ball Valve , Plug Valve , Piston Valve , Diaphgram Valve , Butterfly Valve etc.

b) Throttling Valves : Globe Valve , Butterfly Valve , needle valve etc.

c) Non Return Valve : Swing Check Valve , Lift Check Valve.

E) Pressure Gauges : A pressure gauge is very important as it tells us the pressure developed by the pump and system.

Suction Pressure Gauge : This is very important as it helps us to first convey whether suction is positive or negative. And also it informs us the actual pressure in the suction line so that we can account it in head calculation.

Discharge Pressure Gauge : This is of utmost important and also mandatory. Many things can be concluded with the help of reading of Discharge pressure gauge. We come to know the shut off head of the pump by fully closing the discharge valve. We can also know the pressure range at which the pump is operating and we can also get the pump running in preferred operating range with the help of throttling the discharge valve.

During Troubleshooting of the pump , suction and discharge pressure gauge play a very very important role.

This is also important while calculating the actual efficiency of centrifugal pump on site.

F) Strainer: A strainer is generally recommended in the suction pipeline before the pump so that any unforeseen particles , solids , glass etc can be blocked by it. Generally if a strainer is not put then there is always a chance of these particles entering the pump and it may cause severe damage to the pump if the pump is not able to bypass it.

It may also cause a big emergency and can lead to shaft breakage , impeller vane damage etc.

There are different types of strainer like Basket type strainer , Y-Type strainer etc. Based customer requirement they can choose.

This is a very basic schematic of a proper pumping system and if followed properly then the pump breakdowns will be very less.

I hope i have explained the topic well and have given justice to the topic. Incase of any doubts / comments / feedbacks then please feel free to write to us.

Thanks and Regards

Siddharth Deepak Bhimani…

Sial Valves Co…Authorised Dealer of M/s Kirloskar Brothers Ltd.